A superior example of a modern strengthening material

Our products are a superior example of a modern strengthening material made up of hyper performance fibers secured and encased in a polymeric sheath.

Hyper Fibers products are customised for a variety of demanding engineering sectors, from construction to off-shore, from military to agriculture, with unlimited applications.

About us

Hyper Fibers is a new and innovative Italian company focused on development, manufacture and sales of a range of engineering materials used across the world for many purposes. The core of our products is our very own HFW webbing strip.

The basic technology of the business is extrusion of synthetic shears around high tenacity textile cores. The basic product so produced is of flat webbing configuration.

HFW is the ideal synthetic alternative to steel reinforcement and strips, due to its excellent chemical stability and its low creep performance.

Main Applications

Civil Engineering

Used extensively in reinforced soil structures, embankments and underground mining where the polymetric sheath provides immunity to attack from a variety of aggressive soil environments.

Soft Soil

With the highest strength available in the market, our products can be designed for long term application under embankments on soft foundation soils, over voids or piles.

Unlimited Application

The end-products are speciality items which can be tailor-made to suit customers’ particular requirements. And a whole host of other unique products that are beign used increasingly to solve problem in novel ways.

Hyper Performance

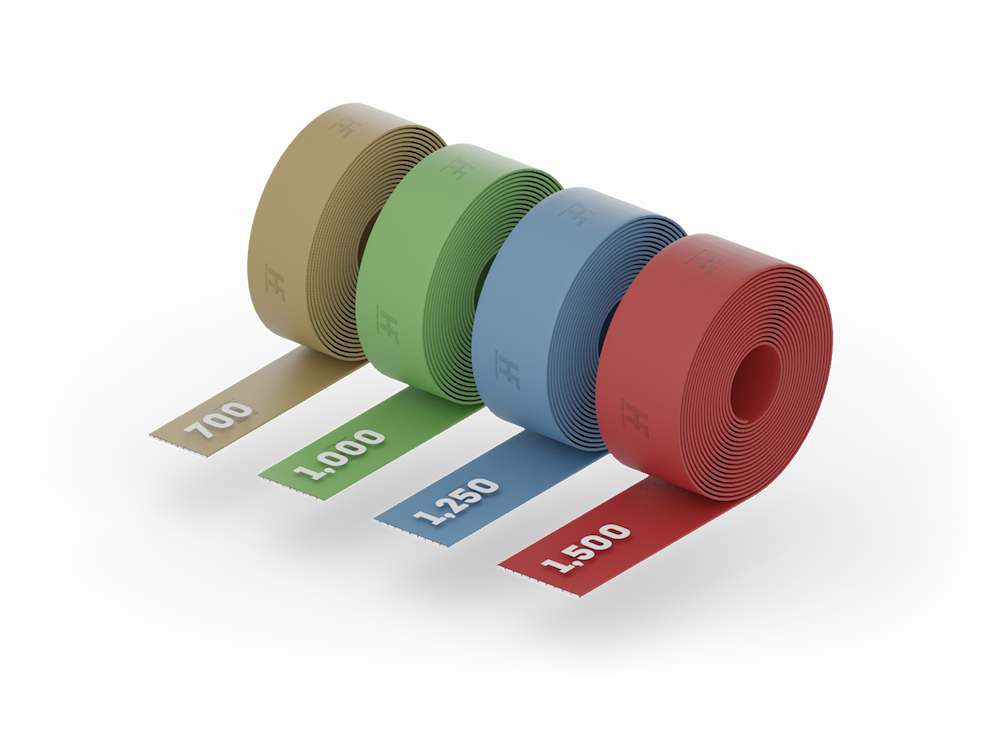

MECHANICAL STRENGTH

Customised range of tensile strength from 1 kN to 2000 kN of ultimate tensile strength per meter of width.

CHEMICAL AND BIOLOGICAL RESISTANCE

Resistance to all natural occurring soil alkalies and acids, as well as seawater. Our products are also unaffected by bacteria, fungi etc.

TEMPERATURE STABILITY

Stable over the range - 50°C to + 70°C.

EXPOSURE TO SUNLIGHT

Hyper Fibers products could be delivered in different colours with additives to protect it from the harmful effects of ultra-violet rays.

ABRASION RESISTANCE

Good resistance to abrasion caused by the action of hard angular objects or stone under heavy loading or tracks of construction plants.

CREEP

Most materials when subject to a load over a long period of time suffer from creep. The creep of our products is extremely low and has proved to be negligible in practise. If properly considered, the design load given can be sustained for a period in excess of 120 years.

STRESS RELAXATION

No detectable change in stress level.

EXCEPTIONAL FATIGUE STRENGTH

The core yarns used in the manufacture of Hyper Fibers products are also used in the construction of car and truck tyres when high fatigue is essential.

ENVIRONMENTAL

Even though the microplastic emissions of our products are extremely low, we strive to reduce them even further to an absolute minimum.

CORROSION

No restriction on the chemical composition of the fill material. The capsule sheet used to protect the core yarns will suffer no deterioration form burial in wet soil conditions, providing excellent resistance to biodegradation.

WATER

No significant loss in strengths when Hyper Fibers product range is immersed in water with the end ends sealed.

INDEPENDENT TESTING

Working with respected independent laboratories we validate, test and certify our systems in compliance with local and international standards.

Customised Technical

Performance

- Ultimate tensile strength

- Modulus

- Extension under load

- Abrasion resistance

- Flame retardant

- Type of coating

- Colour & visibility

- Flexibility & weight

- Embossing

- Long term performance

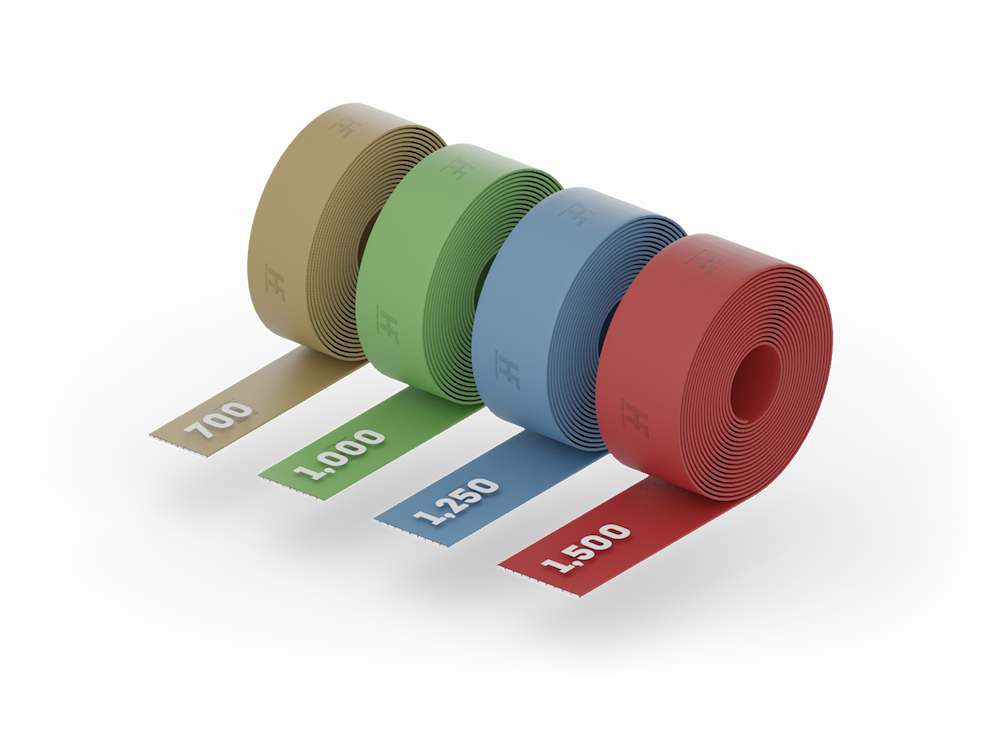

Our wide range of webbing products are manufactured in widths of up to 300mm from a variety of yarns that are from natural or high performance synthetic fibres. The type of fibre chosen may depend on its application as well as customer requirements.

100% Made in Italy

Bespoke Production

Variations in strength, width, physical properties and durability can all be met. Combinations of fibre and sheath types can be varied to meet individual project specifications.

HFW strips are generally supplied in bobbins but composite products on a roll or panel are also possible. HFW is then combined and evenly spaced to create a two-dimensional structures of non standard strengths, widths and lengths to suit specific applications.

Wide range of products

Hyper Fibers is capable to manufacture a complete range of reinforcement materials for soil reinforcement (walls, slopes, embankments) and pavement (paved, unpaved).

Contact Us

Any questions? Email us at hyper@hyperfibers.com or fill out the contact form and we will be in touch.